EUI/EUP Tester Cambox with computer

Ⅰ. Main Functions and Scope of Application

The unit pump control box is suitable for testing electronically controlled unit pumps and pump nozzles.

The main function:

1. Speed display

2. Editing of driving parameters

3. Single or double valve test

4. BIP display settings

5. Fuel injection delay display (optional)

6. Driving feature editing

Ⅱ. Test Preparation

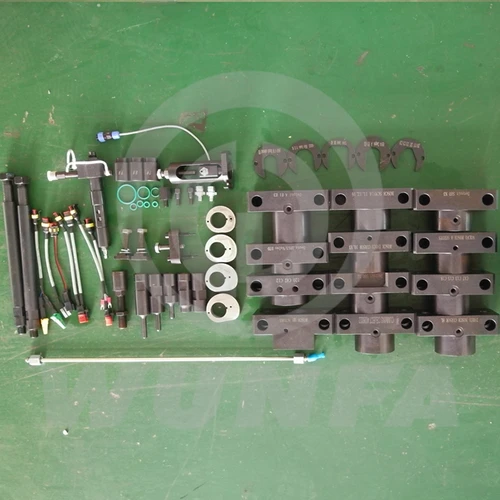

1. Unit pump Clamping and Fixing

The unit pump cam box is clamped on the test bench for testing, fixed on the guide rail, and the injector to be inspected is clamped.

2. Control Box Wiring

The rear panel of the unit pump control box is shown in Figure 2.1.

Please connect the patch cord on the rear panel of the control box as shown in the figure. Connect the power socket to the AC 220V power supply and turn on the power switch.

3. Test Bench Wiring

After the line at the rear of the control box is connected, the line of the main motor driving control box is connected. Finally, the main power line is connected according to the corresponding power distribution of the test rig. Make sure there is no error, the test can be started.

Ⅲ. EUP/EUI Test Preparation

1. Test Bench Power Supply

Open the main switch on the test bench side and prepare the main motor.

2. EUI/EUP Test instructions:

A. Check the ohmic value of the injector solenoid valve.

B. Move the main drive disc by hand to ensure that the camshaft rotates 360° without jamming.

Adjust the injector to run the maximum stroke on the cam box and keep the same ejector height for the same set of injectors.

C. Test the oil pump motor start button, the oil pump starts the oil supply, and the same group fuel injector uses the same oil supply pressure.

D. Call out the control box test data and keep the same test plan for the same group of injectors.

E. Start the main motor to test the oil quantity and find out the products with inconsistent oil output for maintenance.

3. Main motor operation

Set the appropriate speed on the main motor drive control box and run the main motor

4. Operation of the unit pump control box

1) On the main interface of the unit pump control box, check whether the communication light is in the green light state, the green light indicates that the communication is normal, and the red light is abnormal.

Note: The user needs to select the injector model to be tested, please go to the management settings – user login – return to the main menu – test settings to enter the part to be tested.

2) Log in to the user, click the “Log On” button in the upper left corner of the test interface, and the login dialog box will pop up. Enter the password 654321 and click OK to log in successfully.

2) Select the type of valve to test the unit pump. After confirming, click the “Back” button on the interface to return to the main test page.

3) Click “Test start” to drive unit pump injection.

Ⅳ. Data storage and modification

1. After the administrative user logs in, we can modify the driving parameters in the test database.

Select the data to be changed in the driving parameter bar, pop up the data input box, and re-enter it to modify it.

2. Editing of drive characteristics

1) Modification of drive characteristics

a. Click the “Driver Feature Edit” button on the EUP/EUI test interface to enter the “Feature Edit” interface.

b. Click the “Previous” and “Next” buttons to select the feature to be changed, confirm the feature number, click on the data to be changed, pop up the data input box, and re-enter it to modify it.

2) Deletion of drive characteristics

Click the “Previous” and “Next” buttons on the “Feature Edit” interface to select the features to be deleted. Click the “Delete” button to delete the feature.

3) New driver features

Click “Data Import/Export” on the “Feature Edit” interface to enter the next interface. Click “Data View” to pop up the “Recipe Edit” interface to view the features that are included in the control box system. Click “Add” to add features. Enter each parameter as needed, and click “Save” when finished. In the “Recipe Edit” interface, you can also modify and delete the drive features to complete all editing of the drive features.

1) Modification of drive characteristics

a. Click the “Feature Edit” button on the EUP/EUI test interface to enter the “Feature Edit” interface.

b. Click the “Previous” and “Next” buttons to select the feature to be changed, confirm the feature number, click on the data to be changed, pop up the data input box, and re-enter it to modify it.

2) Deletion of drive characteristics

Click the “Previous” and “Next” buttons on the “Feature Edit” interface to select the features to be deleted. Click the “Delete” button to delete the feature.

3) New driver features

Click “Feature Number” on the “Feature Edit” interface to enter, modify the original feature parameters to add new features, input each parameter as required, and click “OK” to save. In the “Recipe Edit” interface, you can also modify and delete the drive features to complete all editing of the drive features.

4. Import/export of data

Insert the mobile device at the USB interface on the back of the touch screen, and click “Data Import” or “Data Export” on the “Data Import/Export” interface to complete the corresponding operation.

Ⅴ. Common faults and troubleshooting methods

Although high-reliability component assembly is used, unexpected failures occur for some reason, so please quickly eliminate them according to “Troubleshooting”. The specific faults and troubleshooting methods are shown in Table 1 below. If you encounter other problems that cannot be solved, please contact our company.

Chart One

|

Unusual |

Checking |

Resolution |

|

Rotating Speed |

Check if the speed signal line at the rear of the control box is plugged in. |

Connect the patch cord |

|

The main motor |

Check if the pump is activated |

Start test oil pump |

|

Control box |

Check if the screen communication port is abnormal. |

If there is a problem with the communication port, replace the communication port. |

|

Unit pump valve |

Check if the line of the Unit pump valve is connected |

Patch cord check |

| Check if the driver parameters are set correctly. |

Modify drive parameters | |

| Check if single valve and double valve are not selected |

Select valve type |

Reviews

There are no reviews yet.