1 Outline

1.1 Outline

CRS300 high pressure common rail system controller function is to mimic the diesel engine ECU (Engine Control Unit), While providing Bosch, Delphi, Siemens and other common rail system control signal to drive the high-pressure common rail injector and Common rail pump to work,drive signal parameters can be carried out by the user according to their actual situation, and can be saved grouped for easy maintenance personnel to high-pressure common rail injector in working condition to judge different conditions and maintenance。

1.2 Features

1、Support the Electromagnetic injector and Pizeo injector;

2、Supports up to six Electromagnetic injector;

3、Support for multiple rail pressure sensor;

4、Intelligent PID algorithm, the pressure control is more precise;

5、The software and hardware double short-circuit protection, Run Safer;

6、Multi-language selection, Chinese/ English/ Russian;

7、Security designed to prevent operator misuse, use more secure;

8、Customizable boot LOGO;

9、According to customer demand for customized software interface, operation, chassis appearance;

1.3 Security

To ensure safe operation, please follow the following rules:

1、in the course of operating the tester, the operator should wear safety glasses;

2、using a separate dedicated outlet and reliable grounding. The tester is a three-wire power cord plug is connected to a standard three-wire outlet, please ensure reliable grounding;

3、if the power supply voltage is unstable, please connect the power supply voltage tester uses;

4、regularly check the AC power cord is damaged, and the power plug or power outlet for dust accumulation;

5、if the tester abnormal conditions occur, or an abnormal sound or smell, or the tester can not be hot to the touch, stop using it immediately and unplug the AC power outlet power cord and all other cables;

6、if the tester fails, please contact the service personnel to obtain necessary assistance;

1.4 Use and maintenance

1、Do not throw, drop or step on the tester, the tester to avoid being a strong external impact;

2、Do not insert foreign objects into the connector portion tester;

3、Do not allow water or other liquids to flow into the interior or on the tester tester;

4、do not touch with wet hands AC power cord terminals;

5、do not let dust or foreign matter on the terminals around the AC power, the AC terminals on the accumulation of dust and foreign matter may cause a fire or electric shock;

6、avoid stepping on or pinched AC power cord;

7、unplug the power cord when cleaning the tester.

2 Accessories and Interface Description

2.1 Wire of injector

2.2 Wire of pump |

2.3 Wire of Rail pressure sensor |

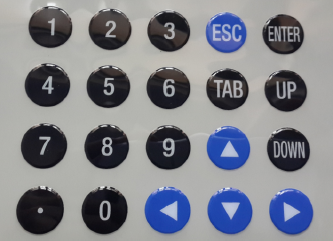

3 Operating Instructions 3.1 Keyboard Layout

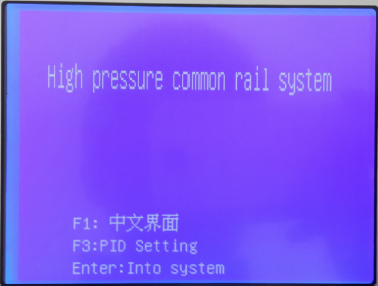

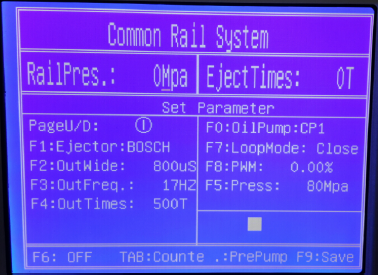

F1 Chinese, English, and Russian F3 PID settings; ENTER to enter the test page; 2. Press the F3 key to enter setup PID parameter settings: F0: Select common rail pump, F1: Set scale value, the reference value: 0.5; F2: Set the integral value, reference value: 0; F3: Set differential value, the reference value: 6; Pressure sensor is provided: F5: zero value F6: full scale value 3、Press ENTER into test page:

PageU / D: Select the parameter list F1: Select injectors, continuously press F1 F2: Set the pulse width, enter number , F3: Set the frequency, enter number, F4: Set count the number of times, F6: start testing and stop the test, Note: Before starting the test, TAB: start and stop counting, F0: Select the pump model, F7: Select control mode, F8: Sets the initial PWM value, The setting range of 0 to 100%; F5: set pressure value, Setting range 0 ~ 160Mpa; F9: Save the current parameters; Dynamic adjustment: 4 About maintenance responsibility 1、 Under normal use, |

Reviews

There are no reviews yet.