A、 Satic test

After the pump assembly is completed, connect the cable, do not turn on the power switch, use a multimeter to measure static resistance, refer to the following table:

| Static Test Table | ||||||

| Temp. | Drive actuator |

Position Sensor |

Temp Sensor |

|||

| Pin | Unit: Ω |

Pin | Unit: Ω |

Pin | Unit: KΩ |

|

| 22.5℃ | 5~ 6 |

0.4~ 1.5 |

1~ 2 |

5.7 ~7 |

4~ 7 |

1.2~ 4.0 |

| 2~ 3 |

5.7 ~7 |

|||||

| 1~ 3 |

10.5~ 12.5 |

|||||

| 60℃ | 5~ 6 |

0.45~ 1.3 |

4~ 7 |

0.3~ 1.8 |

||

| 22.5℃ ~60℃ |

9~ 10 Timing device |

14.3~ 21 |

||||

| 8~ 9 Oil |

8~ 12 |

|||||

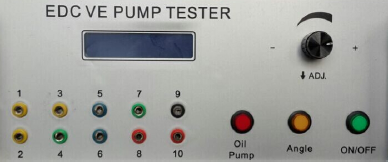

B、 Chassis panel

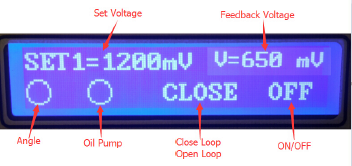

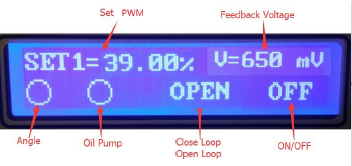

C、 operating instructions

1、The default boot into the closed loop mode, four sets of parameters can be preset,short press ADJ button to switch the packet, turn the knob to adjust the current value:

2、Long press the ADJ button to switch to the open-loop mode,four sets of parameters can be preset,turn the knob to adjust the current value:

3、Oil pump button control supply oil solenoid, you need to open at repair the pump;Angle button control Timing solenoid, opens at 400 rpm.

4、Long press oil Pump button into setting:

You can set the voltage value of SET1~SET4,

Press ADJ button to save the current values and packet switching, swirling around ADJ key to change the current value,

Factory items, whether to restore factory default,

swirling around ADJ button to select Yes or No, press the ADJ button to confirm.

D、 Dynamic Test

Reviews

There are no reviews yet.